Two-part retention packaging

Maximum protection for many products in many shapes thanks to membrane film!

High flexibility thanks to two-part retention packaging

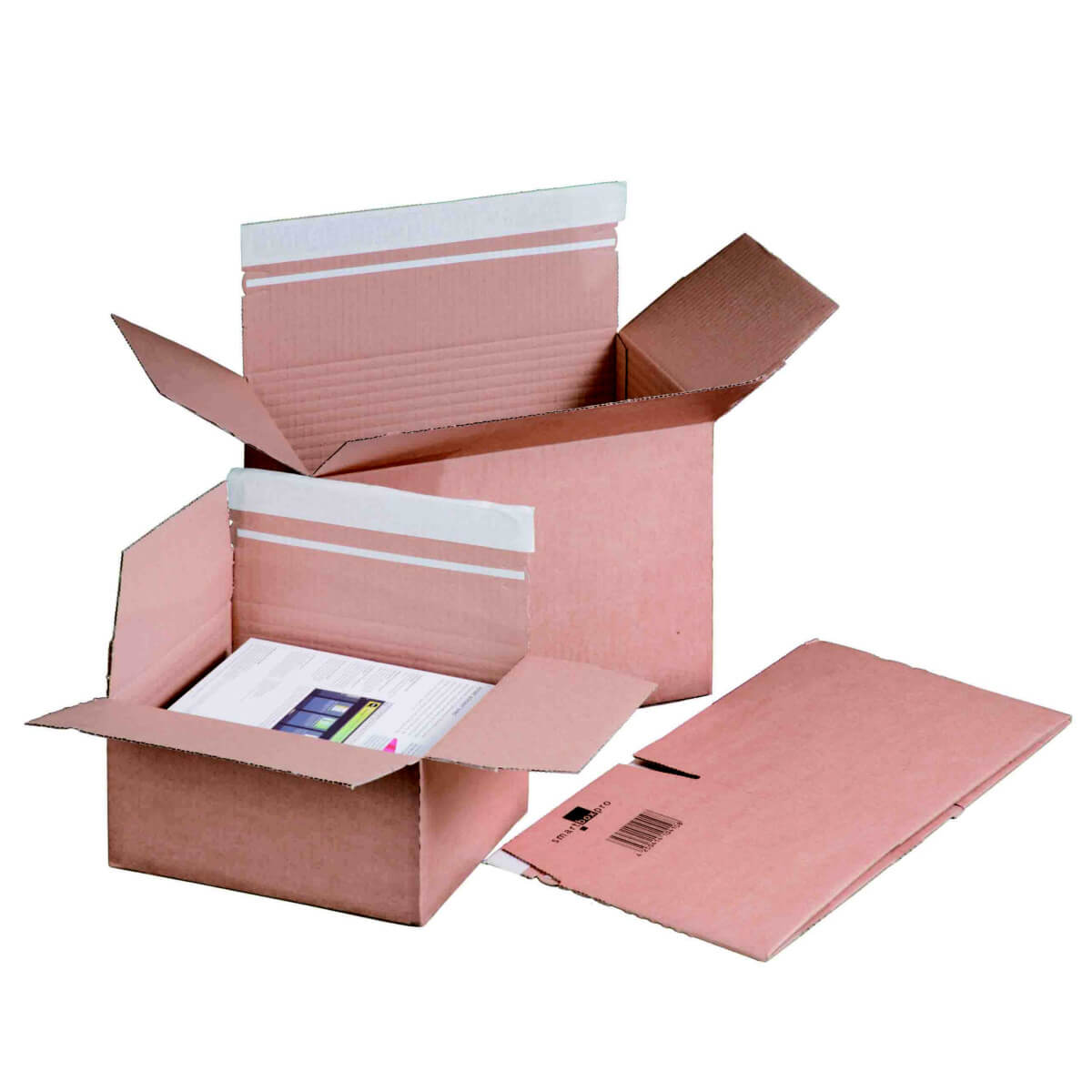

The two-part fixation box clearly scores points over the one-part fixation packaging, especially due to an increase in flexibility. Here, the product is packed in a separate film bag made of recyclable membrane. An additional outer carton provides greater security.

Components of a two-part fixation pack

If you decide to purchase two-part fuser packaging, you will receive two parts per packaging. These are the outer carton made of high-quality corrugated cardboard and a stretch carrier with integrated film. The film is extremely elastic, which means that it remains adaptable and adapts easily to different types of products. The design thus allows safe shipping for various articles.

Innovation: Retention packaging

While many packaging solutions rely on outer cartons to provide additional protection on the outside of the packaging, the 2-part fixation packaging focuses on the inside. This is where the film is located that is supposed to fix the product. The film is placed on a corrugated board carrier. As long as the cardboard has not been folded, the film is not stretched. This makes it easy to slide the product under the film during handling. The only thing that matters here is correct placement. The product should always be placed in the centre and should not look over the side of the carrier. Only when the position is correct should the film be stretched. To do this, simply fold the construction. The film is automatically pulled tight and taut. Don't worry, as a rule there is no need to worry about tearing and the elastic film also covers sharp-edged objects without any problems. Before shipping, the fixation packaging only needs to be put into a suitable outer box. Caution: If this is not available in the right size and there is a risk of the fixation packaging slipping back and forth inside the box, additional padding should be used. Packing chips or Schrenzpapier can be an ideal solution to cushion hollow spaces and provide more security during shipping.

Package your product step by step

- Carefully slide the product to be packed under the stretch film of the fusible interlining, making sure it is placed as centrally as possible. An unevenly shaped object should ideally lie flat against the box.

- Fold the flaps of the fusible interlining over to stretch the film. This process serves to fix the packaged goods.

- Raise the side flaps of the fusible interlining to prepare it for shipping

- You can now place the fusible interlining in the outer box that has already been set up.

- Seal the outer carton. If necessary, use further cushioning material if there are larger cavities inside. If you only use the resealable sealing flap for the closure and no additional adhesive or parcel tape, you can send the goods as an open consignment at a particularly low price.

The two piece membrane box at a glance:

- Quick to handle

- High protection

- Can be used for various products

- Low processing costs

- Quick closure

- Environmentally friendly. Can be disposed of unseparated in waste paper

- Representative appearance

Lower your process costs with two-part fuser boxes

The goal of most companies is to reduce process costs. Only with low costs for processes and work steps can a corresponding profit be produced that ensures the company's success. Logistical processes such as packaging and shipping products can turn out to be real cost drivers. The obvious decision to use individual packaging for each product can quickly become a risk when one takes a look at the invoice. Two-piece fusible boxes can be the right solution here. With their help, you can reduce your own packaging variety at the packing table or in the warehouse by up to 90%. We will be happy to explain why.

Packaging adapts individually to the product

In most cases, the packaging must be chosen to fit the product. A small, flat item should be packaged differently than a medium-sized one. If uniform packaging sizes are chosen after all, at least a lot of padding must be used. In every carton there are large and small cavities that can become a danger to the product and the carton. It is important that the product cannot move back and forth during transport, but is firmly fixed. With other packaging, such as the 1-wall folding carton, packaging chips, bubble pockets or tissue paper are used, for example, to fix the product. This is not necessary with our fixing cartons made of two parts, as the tear-resistant stretch film is highly flexible in its composition. As a result, it clings to different contours and surfaces like a second skin. It doesn't matter whether your goods are smooth, nubby or thorny. With the fixation box you stabilise every product and prepare it safely for shipping. Slippage is prevented after tensioning the film.

Ready for shipping in a flash

Not only the fixing boxes are already prepared. Setting up the outer boxes is also child's play. The boxes, which you can find in the right size in our online shop, are already pre-glued and can therefore be erected in no time at all. This not only saves you packaging materials and filling materials, but also considerably reduces packaging time. The automatic bottoms of the outer boxes allow for quicker handling, which pays off quickly in practice.

Labelling and franking your shipment correctly

Two-piece fuser boxes come in many different sizes, which can also result in different prices in terms of shipping costs. However, with Verpacking's shipping packaging you can also save on larger parcels by sending them uninsured as open goods shipments. For this purpose, it is important that the outer carton is not glued, but only sealed with the sealing flap. In this way, it is possible for the post office to check later that the goods were really sent using this method. You benefit from particularly low-priced conditions. In addition to legibly stating the addressee and sender, you should also clearly mark the box with the words "Warensendung".

Fixation boxes are reusable

If handled correctly, 2-part fixing cartons can be used several times for shipping without any problems. This is interesting, for example, when customers want to return goods to you. When opening the box, the fixing film does not have to be damaged. Simply unfolding it loosens the tension so that the product can be easily taken out again. When returning the product, it can be re-clamped in the same way and fixed in the box one more time. This makes the carton, which can be disposed of unseparated in waste paper after use, particularly ecological.