- Fefco: 0110

- Welle: 2-wellig

- Menge pro Palette: 250

- Qualität: 2.2BC

- no express service, no self pickup

Reordered, delivery time 6-11 days

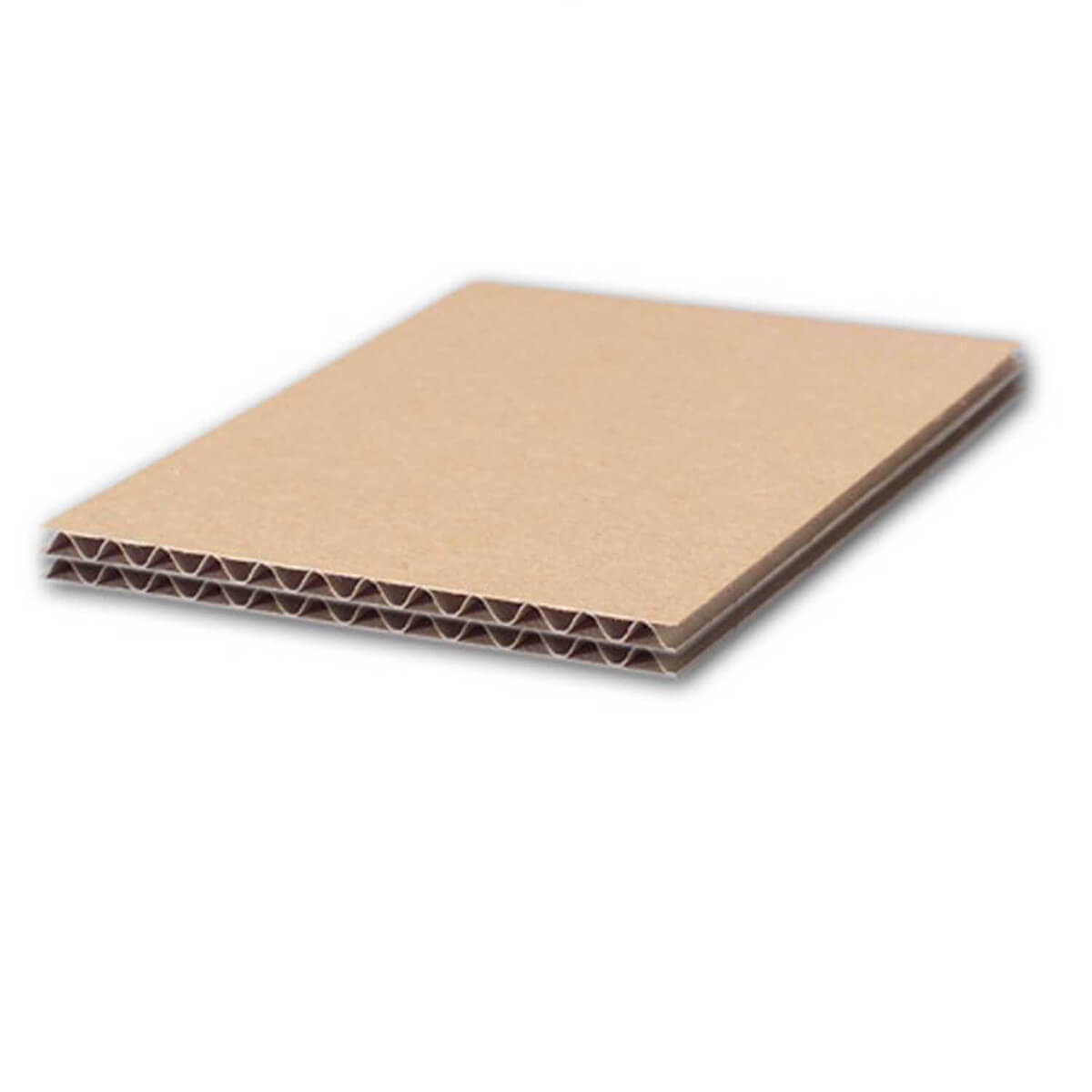

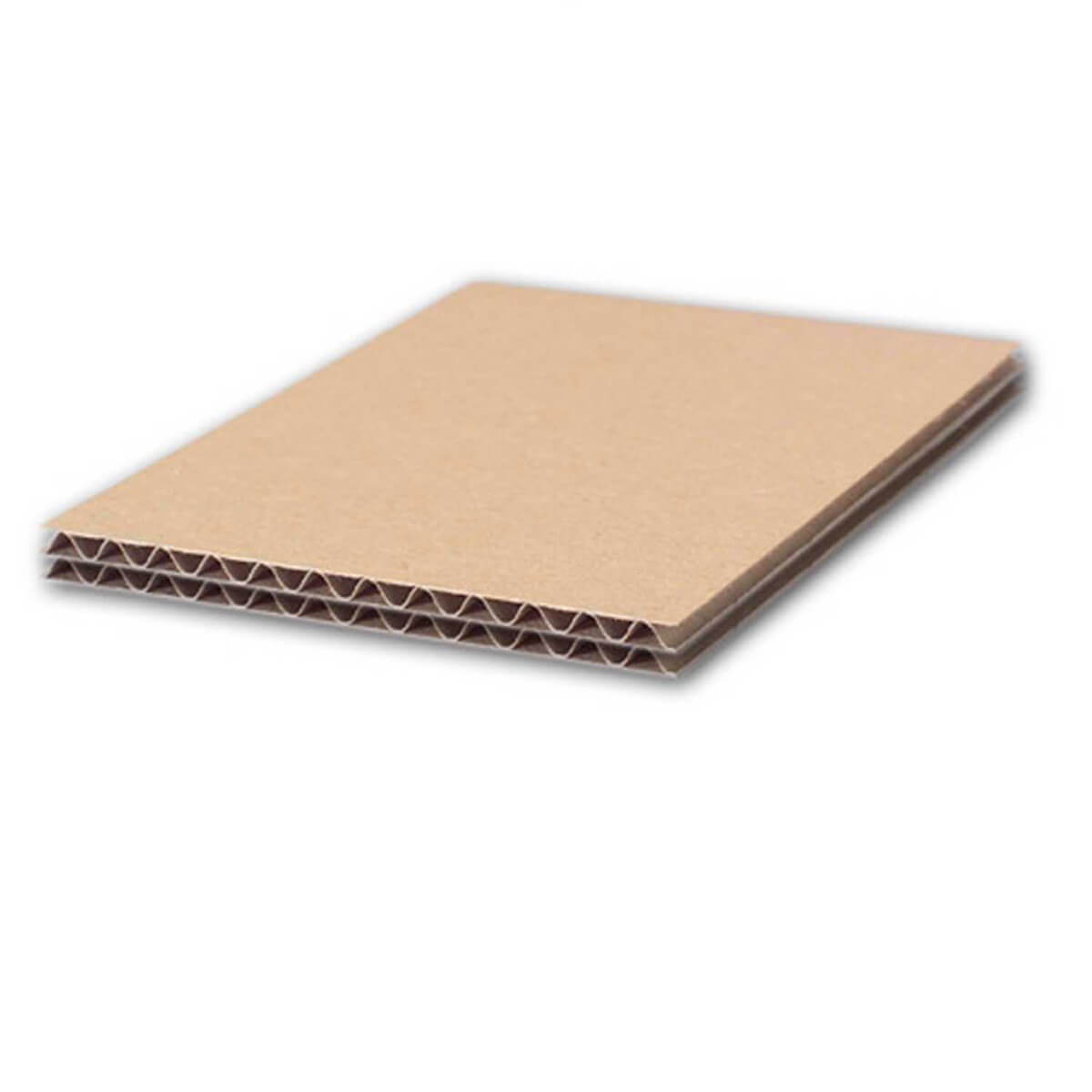

- Cardboard blanks

- Dimensions: 500 x 500mm

- Corrugated cardboard: double wall

- Fefco: 0110

- Flute: 2.2BC

- no express service, no self pickup

- Fefco: 0452

- Quality: 2.4BC

- Cardboard: Double wall

- Color: brown

- Additional fold: no

- no express service, no self pickup

- Cardboard blanks

- Dimensions: 780 x 1180mm

- Corrugated cardboard: single wall

- Flute: 1.1C

- Fefco: 0110

- no express service, no self pickup

Reordered, delivery time 6-11 days

- Cardboard blanks

- Dimensions: 750 x 1180mm

- Corrugated cardboard: single wall

- Fefco: 0110

- Flute: 1.1B

- no express service, no self pickup

Buy cardboard sheets and use them as protective pallet layer pads in logistics.

Cardboard sheets are an indispensable product in the packaging industry and are used in various fields. A blank made of corrugated cardboard provides optimal protection for goods during transportation, storage and stacking on pallets. In this function they are known as intermediate pallet layers. They are an efficient and practical solution for many packaging needs in the logistics sector, but they can also be useful in private spaces, for example, when moving house.

The cardboard panel is an all-rounder in the packaging industry - from interlayer during storage to carpet pad during a move

Cardboard sheets are specially cut pieces of corrugated cardboard used as pallet interlayers to protect, stabilize and secure goods during storage and transportation. They can equally serve as lids for corrugated containers or be used as surface protection for fragile items. With its versatile application, cardboard sheet is an important part of any packaging process and can undoubtedly be used in numerous logistics environments.

Corrugated cardboard sheets can do much more than just serve as pallet liners

Corrugated cardboard sheets are known for their versatile properties, and they score particularly well for their feather-light yet sturdy construction method. However, there are a few differences to consider when choosing the right cardboard panels to suit different needs in the packaging industry.

Cardboard sheet is generally available in single flute and double flute versions. Single wall corrugated sheets offer good stability and are suitable for lighter items, while a double wall cardboard sheet offers increased strength and resilience, making it suitable for heavier or more delicate goods and products. Furthermore, the symbiosis of stability and lightness is important. Despite their stability, cartonboard sheets are light and easy to handle. They can be easily cut to the desired size and adapted to different shapes and sizes. Depending on the type of corrugation, height and division, the various cardboard panels impress with their extraordinarily high stackability. As a result, they can be easily stacked in height and easily withstand high weight differences.

In addition, such a board offers protection to the goods in two ways. The cavities created by the corrugated structure of the corrugated board act as a buffer and enable the board to cushion compressive loads. This in turn protects the goods underneath from damage. Moreover, cardboard sheets offer effective protection against puncturing of other goods. This permanently ensures the safety and protection of packaged products.

Environmental friendliness and sustainability

Paperboard panels are made of about 80 percent recycled paper and about 20 percent paper from thinning wood and breakage. This makes them an environmentally friendly packaging option and makes them popular as an alternative release or lidding solution. They are also fully recyclable and reusable. When cardboard is used as the base material for pallet layer pads, this outer packaging becomes an innovative and sustainable solution for large logistics companies, whose environmental concerns are becoming increasingly prominent.

Why is corrugated board so suitable for the packaging industry?

The use of corrugated board blanks for the production of cardboard panels brings several benefits. First, corrugated board is relatively light compared to other materials, which makes it easier to transport and handle. The voids created by the corrugated structure provide better shock absorption, thus permanently protecting the packaged goods from damage. Likewise, corrugated board is a cost-effective material that is both strong and durable. A fact that should always be taken into account when buying corrugated board sheets. These properties make it an ideal companion for making sheets as pallet liners, making it an effective packaging solution. The corrugated structures are one of the most important properties of the blanks. It is only through these that it is possible to stack and fix the goods on top of each other in such a dimensionally stable way. Despite the lightness of the individual blanks, the waves in the middle ensure maximum hold. This is exactly what makes them so suitable for industry and logistics.

The carton board is a universal solution for a wide range of packaging needs

The versatility of the carton plate makes it an extremely practical and effective packaging solution that can be adapted to various packaging needs. Its flexibility, easy handling and cost-effective nature speaks for popular choice in the packaging industry. Whether used as a base on pallets, an intermediate layer to protect goods, or as surface protection for delicate items. Cardboard sheets offer a reliable solution concept for safe transportation and optimal storage of goods.

A common use of a cardboard sheet is to place it as pallet interlayers cardboard. Thus, pallet interlayers protect pallet surfaces and increase the stability of the goods being transported. The pallet layer pad serves as a protective barrier between the goods and the pallet to completely prevent damage during transportation and storage. A cardboard sheet can also be placed as a layer between the layers of goods on pallets. By inserting pallet interlayers at regular intervals, an additional protective barrier is created that protects the goods from impact, pressure loads and other damage. It also facilitates stacking of individual goods and provides optimal fixation during transportation.

A great advantage of cardboard layer pads is their adaptability to different shapes and sizes. They can be easily cut to the desired size to meet specific requirements. Whether rectangular, square or any other shape relevant to transportation. The pallet liner can be flexibly adapted to provide a need-based solution for individual packaging options.

Sensitive surfaces such as glass, stone or painted objects also require special protection against damage. Thus, the actual pallet layer pads can also be used as a protective layer to avoid direct contact of the sensitive surfaces with other objects. They serve as an additional protective layer and provide a barrier against external influences during transport or storage.

But it is not only in the logistics sector that you can find a useful application for interleaving cardboard. It can serve as a carpet pad during a move or renovation to protect floors from scratches or damage. It is also suitable as a lid for corrugated containers to ensure proper closure and protect the contents from external influences. In printing shops, these boards are often used as a printing base, while in the graphic arts and crafts industry they are used as an inventive material for design. Buying corrugated board sheets is therefore not only worthwhile for mail order companies.

P: Suitable dimensions for individual packaging requirements

Corrugated board sheets are available in a variety of standard dimensions to meet common requirements in the packaging industry and logistics. Single-wall cardboard sheets are available in the dimensions 1180 x 750 mm or 1180 x 780 mm. These sizes provide sufficient surface area to securely fix and protect goods. A double corrugated cardboard panel is available in regular dimensions of 500 x 500 mm or 1160 x 760 mm. The additional corrugation provides increased stability and strength, which is especially beneficial for heavier or more delicate goods.

Apart from the different dimensions, the pallet layer pad is also available in container versions to ensure all-round protection. The pallet layer pad cardboard can thus act as a lid for corrugated containers measuring 1200 x 800 x 125 mm. This enables the containers to be closed securely and properly to protect the contents professionally from external influences.

How intermediate layers of cardboard in various corrugation types ensure that the goods are protected on pallets.

In addition to single and double flute cuts, corrugated cardboard impresses with its different flute types, which, depending on how they are grouped together, form a stable and resilient structure. The choice of the right flute type depends on the specific requirements of the packaging. Sometimes, for pallet liners, lightness is more important than impact resistance. If you are transporting more fragile goods, the pallet liner should in turn be more robust. Here are some of the common types of corrugations and their characteristics:

The A-flute is the oldest of all flute types. It is well suited for packaging that requires high stackability and buffering, but it cannot be printed.

This is followed by the so-called C flute, a medium flute type that offers a good combination of strength and cushioning properties. C-flutes form the good middle ground of all other flute types and can also be printed.

B-flute is suitable for protecting goods that are less sensitive. However, its thinner layer makes it lighter and saves storage space.

E/F flutes are primarily packaging solutions that do not require solid all-round protection. They are mainly used in the sales area, but not in the cut-to-size area.

Effective transport of goods succeeds thanks to cardboard blanks as pallet interlayers

Cardboard sheets play an important role in the packaging industry and offer numerous advantages for the safe and effective transport of goods. Not for nothing are they called all-rounders and true all-rounders in the logistics sector. Throughout Germany, they have an impressive total market share of around 65 percent and are also used as heavy-duty corrugated board, which is known for its high stability.

They are primarily used as an intermediate layer on pallets with transported goods and provide a stable and flat layer to underlay various goods. Pallet layer pads blanks effectively prevent slipping and movement of goods during transportation, which significantly reduces the risk of damage. Cardboard sheets serve as an additional protective layer for fragile goods. They ensure that sharp objects or pointed edges do not penetrate the carton and prevent dirt or dust from getting into the products. In addition, they provide effective cushioning of pressure loads that may occur during transport.

For logistics and industry, it's more important than ever to save space and meet budgets effectively to keep the design in the warehouse as efficient as possible. Thanks to low-cost blanks and space-saving solutions, this is possible. With the help of blanks, goods can be stacked in height, creating space on the level. Further loading and handling of the goods is also facilitated and ensures smooth logistics processes. In addition, personnel costs as well as storage costs are saved, as the goods can be arranged in a space-saving manner and employees act faster in the handling of goods. Working hours can be saved as well as unnecessary return transport costs can be avoided, as the blanks can be disposed of and recycled at the place of delivery.

The advantage of corrugated containers lies in the proper sealing of various contents as well as protection against dust, moisture and shocks. This ensures a reliable and safe packaging solution during transportation and storage. As an environmentally friendly alternative to conventional packaging materials, they also help reduce waste and environmental impact. Thus, they are a guarantee for sustainability and serve to reduce the ecological footprint. These versatile benefits make carton blanks an indispensable component in the packaging sector. They provide protection, stability and security for all conceivable goods during transport as well as storage, and ensure that they arrive at the recipient in top condition.

Tips for buying blanks - what to look for to make the right choice?

By using blanks, goods can be safely stacked and secured on pallets. The different dimensions and designs of cardboard sheets allow flexible adaptation to different products and packaging requirements. In addition, they provide all-round protection from external influences and serve as additional floors in the pallet stack. However, when buying cardboard sheets, it is crucial to pay attention to the quality, price-performance ratio, as well as the material and adaptability to one's needs. Relevant purchasing decisions are made in order to select the right blanks for personal requirements in the end. These important aspects help to make the right purchase decision and in the end to choose the optimal blank.

Quality of the cardboard panels

Pay attention to the quality of the cardboard panels to guarantee that they are sturdy, stable and durable. Check the material, the thickness of the board and the strength of it. This will ensure that they meet the requirements of your own packaging needs. At Verpacking.com, you will get only the highest quality blanks that will provide the best protection for your goods.

Good price-performance ratio

Compare the prices of different blanks to get the best value for your money. Take into account the quality, size and quantity of the pallet liners. Sometimes it can be worth investing more than the minimum order quantity to get volume discounts.

First class material quality

Also take note of the material that the cardboard sheet is made of. Make sure that it is high-quality corrugated cardboard, made from recycled paper and a certain amount of thinned wood. This not only ensures good stability, but also an environmentally friendly packaging solution.

Adaptability of the blanks

Consider what size and shape of cardboard panel is needed. One advantage of corrugated boards is their adaptability. They can be easily cut to the desired size to meet the specific requirements in the packaging application. Make sure that this option is offered and that the cuts can also be customized afterwards.

Calculated minimum order quantities

Also check the minimum order quantity, which ranges from 250 to 400 pieces for the cardboard boxes, depending on the blank. Depending on the blank and the size of the cardboard interleaving, various minimum purchase quantities are required. In order to select the optimal requirement of the blanks, it is important to order them in an economically sensible way without having to repeatedly reorder smaller quantities. Calculate how many cardboard boxes are regularly delivered and how many blanks can be expected within a month. Based on this, the corresponding requirement for the half-year or year can be calculated.

These tips speak to purchasing a high quality paperboard for individual packaging needs. Compare quotes, pay attention to quality, and customize blanks to meet personal needs. This will ensure the best cost-benefit ratio and goods will always arrive intact and protected at the recipient's door.

Overall, blanks are an effective and practical solution for packaging goods. They offer stability, protection and flexibility and help ensure that products reach their destination safely and undamaged. Their environmentally friendly properties also make them a sustainable choice in the packaging industry. Buying cardboard sheets, and thus investing in high-quality pallet liners, is worthwhile because they ensure convenient transportation and effective storage of all kinds of goods. This means that nothing more stands in the way of a safe packaging experience.